OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

2026 Best Small Powder Coating Oven Options to Consider?

When it comes to powder coating, selecting the right equipment is crucial. A small powder coating oven can make a significant difference. It allows you to achieve professional results without occupying too much space. However, not all options are created equal.

In 2026, several small powder coating ovens stand out for their performance and versatility. These ovens are designed to handle various projects, from small items to larger components. Their compact design means they can fit in tight spaces, yet they still deliver excellent results.

While exploring the best small powder coating oven options, consider your specific needs. The market is filled with choices, but not all will meet your expectations. It’s important to reflect on features like temperature uniformity, airflow, and ease of use. Finding the right balance can sometimes feel challenging, but it can lead to satisfying outcomes.

2026 Trends in Small Powder Coating Ovens: A Comprehensive Overview

In 2026, the small powder coating oven market is evolving rapidly. Trends show a shift towards energy efficiency and compact designs. Many users now prefer ovens that consume less power while still delivering high-quality finishes. Innovative heating technologies are becoming a standard, enhancing uniformity in coating.

Tips: Consider the energy rating when choosing an oven. Higher efficiency means lower costs over time. Make sure to look for ovens that can handle various sizes. Medium to small parts should fit without issue.

User feedback indicates that some smaller ovens struggle with large pieces. This poses a challenge for businesses with diverse product ranges. Balancing size and performance is key for many buyers. Availability of customization options is a notable trend. Manufacturers are now offering tailored solutions to meet specific needs, which can lead to improved user satisfaction.

Tips: Always check for warranty and support services. An ongoing relationship with the supplier can help address issues quickly. Ensure your workspace can accommodate a new oven's requirements. Proper installation is crucial for optimal performance.

2026 Best Small Powder Coating Oven Options to Consider

| Oven Model | Temperature Range (°F) | Oven Capacity (Cubic Feet) | Heating Method | Energy Efficiency Rating | Price Range ($) |

|---|---|---|---|---|---|

| Compact Pro | 350 - 400 | 5 | Convection | A+ | 1500 - 2000 |

| Mini Heat Master | 300 - 350 | 4 | Infrared | B | 1200 - 1700 |

| Rapid Cure Oven | 400 - 450 | 6 | Convection | A++ | 1800 - 2200 |

| EcoSmart Oven | 350 - 400 | 5 | Electric | A | 1600 - 2100 |

| Ultra Compact Oven | 300 - 350 | 3 | Convection | B+ | 900 - 1300 |

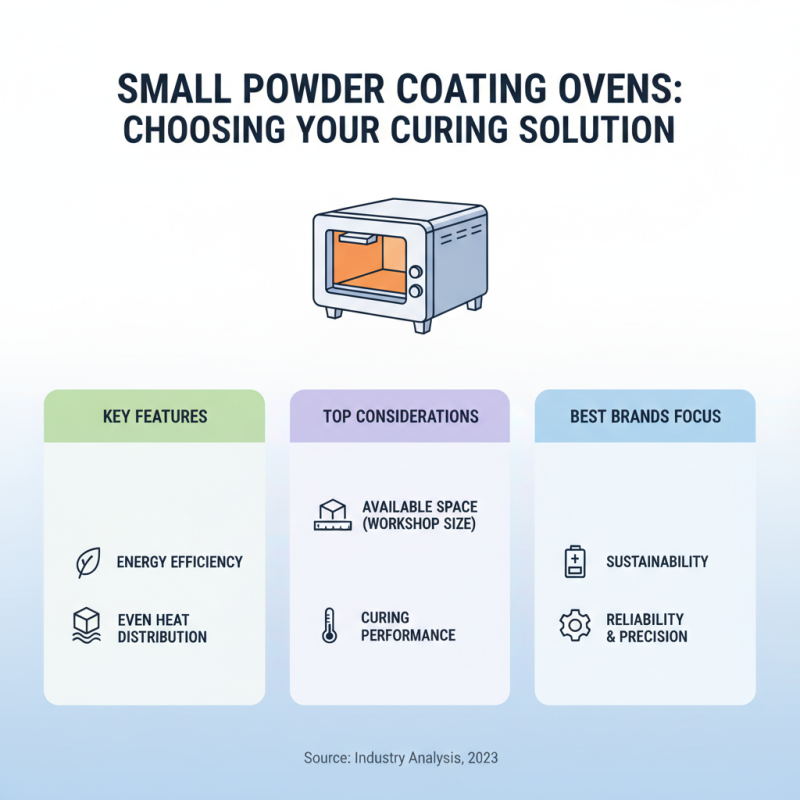

Key Features to Look for in Small Powder Coating Ovens

When considering small powder coating ovens, key features play a vital role in making the right choice. Look for an oven with a sturdy construction. Materials should resist heat and corrosion. A good insulation system is essential too. It maintains consistent temperatures, ensuring quality results. Pay attention to the oven's size. Make sure it fits your workspace without compromising mobility.

Temperature control is another crucial factor. Digital controls offer precision, helping to achieve optimal curing times. An adjustable airflow system can enhance coating performance, improving finishes. Safety features such as auto shut-off should not be overlooked. They prevent overheating and ensure safe operation. Furthermore, consider how easy the oven is to clean and maintain. Learning to manage these aspects is part of the journey in finding the perfect oven.

Lastly, think about energy efficiency. Ovens that consume less power can lead to cost savings over time, but they may require more time to reach desired temperatures. Balancing these factors can be challenging. Reflect on your specific needs before making a decision. Not every model meets all requirements perfectly, and that’s okay.

Top Brands for Small Powder Coating Ovens in 2026

When it comes to small powder coating ovens, the choices can be overwhelming. Each option offers unique features that cater to various needs. The best brands focus on energy efficiency and compact designs. They provide impressive heat distribution and even curing. It’s essential to consider how much space you have. While some ovens fit neatly in small workshops, others require more room than expected.

Another vital detail is temperature control. Accurate temperature settings ensure the best results for your projects. Some models have digital displays for easier monitoring. Users often reflect on how having precise controls impacts the final finish. A well-calibrated oven can make a noticeable difference in quality. Yet, finding that right model can be challenging. Many struggle with customer support and maintenance after the sale.

The construction of the oven also matters. Durable materials withstand high heat, leading to a longer lifespan. However, weight can be an issue for some users. Heavier units might feel more stable, but they can be difficult to move. Always consider these trade-offs when evaluating options. Careful research will help identify the perfect small powder coating oven for your needs.

Cost Considerations: Budgeting for a Small Powder Coating Oven

When budgeting for a small powder coating oven, it's essential to consider initial costs and long-term expenses. Basic models typically range from $3,000 to $10,000. However, advanced features can push prices up significantly. For instance, a high-efficiency oven might cost over $15,000. It's critical to evaluate your specific needs before making a purchase.

Utility costs also play a significant role in overall budgetary considerations. According to industry reports, the average energy consumption of powder coating ovens accounts for about 20% of a facility's power use. This could translate to monthly costs of $200 to $800 based on energy rates. Maintenance is another factor. Regular upkeep can add $500 to $1,500 annually, depending on usage.

Investing in a small powder coating oven requires careful financial planning. It's not just about the sticker price. Consider potential hidden costs that could arise. Think about training staff, material costs, and even time lost during maintenance. The decision might feel overwhelming at first, but clarity comes with research and thoughtful consideration.

2026 Best Small Powder Coating Oven Options: Cost Considerations

User Reviews and Ratings: What Customers Say About Small Ovens

When exploring small powder coating ovens, user reviews are invaluable. Customers often highlight the convenience in compact designs. Many appreciate how they fit snugly in small workshops or garages. Yet, some users mention challenges with temperature consistency. Fluctuations can affect the coating quality.

One buyer noted that while the oven worked well initially, maintaining the right temperatures proved tricky. Another user praised its energy efficiency but wished for a larger capacity. Reviews often reveal that while these ovens are effective, they can require careful monitoring. Some find setup instructions unclear, leading to frustration.

Despite these drawbacks, many users celebrate the versatility of small ovens. They can be used for various projects. The feedback often emphasizes the balance between size and performance. This product category seems to attract a mixed bag of reviews, revealing areas for improvement. Users continue to seek ovens that enhance their coating experience.

Related Posts

-

What is Powder Coating Oven and How Does It Work for Your Projects

-

Top 10 Small Powder Coating Ovens for Efficient Home Use

-

Top 10 Benefits of Using Used Powder Coating Oven for Your Business

-

10 Essential Tips for Choosing a Used Powder Coating Oven for Your Business

-

How to Choose the Best Paint Booth Rental for Your Projects

-

The Ultimate Guide to Choosing the Best Mobile Paint Booth for Your Business Needs